First experience with 3D printing

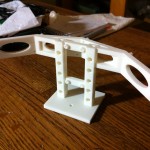

These pictures show the final result of my 3D printing experience. Its a bracket to hold four Parallax Ping))) ultrasonic sensors. This replaces the original three-sensor mount that I fabricated myself from Delrin and Sintra parts, using my Sherline mill. You can see that in the videos in this post.

I created the model in Blender. I can’t really say too much about Blender, other than its best attribute is that it works for what I needed it for, the price is great (free), and its a myth that Blender can’t create parts to specific sizes (it can, it just doesn’t do it by default, and the correct setting isn’t obvious). Its complicated to use, but it did work for me (eventually). It probably took me about 20 hours to learn the software, experiment with it enough to design my part, and create the final model as you see it. There are many, many tutorials online and I’d recommend starting with those if you want to learn anything about Blender.

I printed my parts at Shapeways, a commercial 3D printing service. The service was excellent, very similar to using BatchPCB e.g. create an account, upload the design, pay by credit card, then wait for the results in the mail. My rationale for using Shapeways instead of something like the Makerbot is economics and quality. Although quick turnaround time would be great, the cost plus hassle plus poor quality of the DIY printers (like Makerbot) just isn’t worthwhile to me. I could print 20 of these brackets for the price of one Makerbot. That doesn’t include the cost of my time and frustration figuring out the “science project” required for great results when operating these machines. Its the same argument for why I use BatchPCB instead of making my own PCBs.

The pictured item is actually my second attempt at a 3D print. My first attempt was successful (in as much as it was printed exactly as it was designed) but it wasn’t really robust enough. I learned a lot about wall thickness, joins, etc. In addition to making it stronger, I also improved the design such that no extra pieces were required. If you look closely at the final part, you’ll see that the sensor board mounts are designed right into the part. Just tap the hole then use 4-40 screws to attach the Ping))). So much more convenient than the original part I fabricated myself that required multiple brackets.

My summary: 3D printing is a fantastic technology for making certain types of parts, especially complex shapes from plastic. After a lot of research and observations of people using the Makerbot (and similar machines) I concluded that these DIY printers are too finicky. I’m sure the technology will improve, and I believe I will eventually buy/build a “home shop” 3D printer, but for today Shapeways is a much better deal.

By the way, Shapeways offers metal printing as well as more traditional plastics, but the price is quite high, and I don’t have high hopes for it being as sturdy as something I’d make by milling down a block of metal myself. But 3D printing makes certain designs a lot easier to create. My milling machine and lathe will still get used for many future projects, but sometimes certain objects lend themselves to 3D printing a lot better.